Kesalahan format email

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

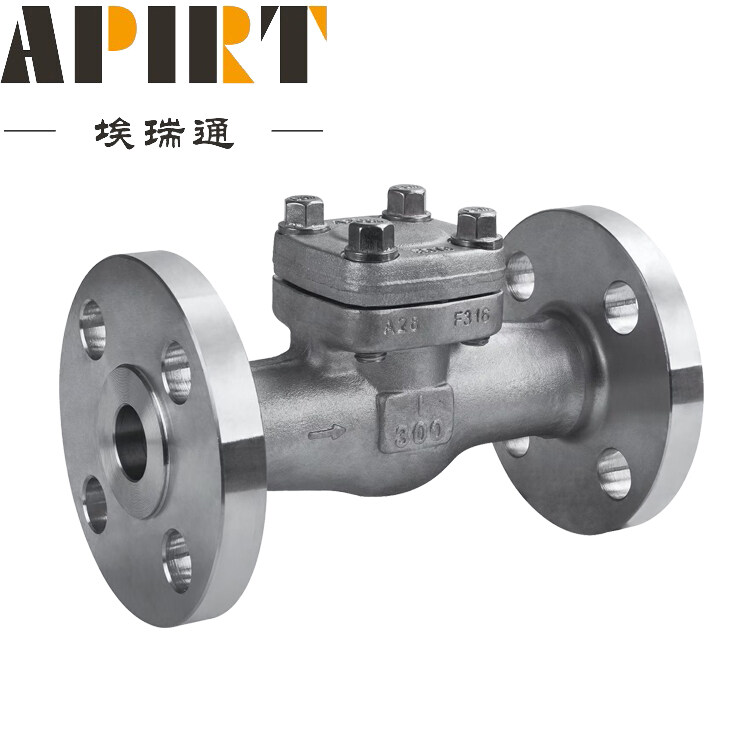

FORGED STEEL CHECK VALVE

The use of forged steel improves durability and prolongs the service life. This product is designed for applications requiring excellent sealing capability under high pressure, low temperature and high viscosity liquids (such as petrochemical products).

Product introduction:

Forged steel check valves use forged steel body and chrome plated brass stem and lever. The material structure improves the durability and prolongs the service life. This product is designed for applications requiring excellent sealing capability under high pressure, low temperature and high viscosity liquids (such as petrochemical products).

Product features:

1. working principle

Forged steel check valve is a mechanical device that allows fluid to flow in one direction and prevents fluid from flowing in the opposite direction to prevent backflow. The check valve is the best choice for the processing industry, which needs a clean and safe environment and the ability to prevent pollution.

2. forged steel check valves prevent backflow in the piping system. The purpose of the check valve is to allow the fluid to flow in only one direction. In the air conditioning or refrigeration system, if there is no condensate pipe in the system or the condensate pipe is discharged into the external drain pipe, check valves shall be installed on both sides of the expansion tank.

3. our forged steel check valve is a manifold or flow control device to prevent backflow and keep the fluid in the desired direction. This valve features a stainless steel body that will not corrode or rust over time like other materials. This is a good solution for water, oil and other fluids that need to be controlled in the pipeline.

4. check valve for gasoline or diesel oil tank - ASTM f1281 forged steel check valve is an ideal product for oil storage tank, which can prevent fuel from being siphoned back to the tank. These check valves are simple to install and their function is to allow gas to flow in one direction while preventing other liquids and / or air from entering the system. Great product, great price!

5. it is an ideal choice for checking flow and pressure. This forged steel check valve is used for flow control and pressure relief of fluid pipelines. It is quick and easy to install without tools, because it has an integral flange, a discharge pipe and an optional online spool. This forged steel check valve provides a strong and reliable seal, making it an ideal choice for many applications. It is designed for pumps, industrial machinery and other pressure filled systems.

6. materials

Better forged steel check valve. Better performance. More value-added. Forged steel check valves are designed to ensure maximum flow and performance while resisting corrosion and wear. In addition, its durable structure makes it more reliable than cast iron valves and less prone to leakage. Forged steel check valve. Adjustable high performance check valves are designed to improve system performance. This is a non-metallic thermoplastic valve that can withstand pressures in excess of 1000 psi and temperatures up to 300 degrees Fahrenheit. This check valve can be used where the wall thickness is not important, and no drilling or punching is required during assembly. The bottom of the valve body is machined with grooves to facilitate installation and will not interfere with other parts during assembly or maintenance. It is easy to adjust and contains no metal, so there will be no corrosion or wear problems.

Flanged Type Forged Swing Check Valve

Applicable Standards:

Gate valve, API602

Steel Valves, ASME B16.34

Face to face ASME B16.10/MFG’S STANDARD

Socket Welded ASME B16.11

Screw Threaded AEME B1.20.1/BS 21

End Flanges ASME B16.5

Butt welding ends ASME B36.10M

Inspection and test API 598

Material: Forged Steel (A105N)

Size Range: 1/2"~2"

Pressure Rating: ASME CL, 150, 300, 600, 900, 1500, 2500

Temperature Range: -196°C~600°C

| Brand | DIDTEK |

|---|---|

| Structure | Check |

| Valve Material | Didtek provide cast steel, stainless steel, special alloy, CI, DI etc |

| Valve Type | Didtek Produce Check Valve |

| Valve Test | 100% quantity tested before delivery |

| Valve Guarantee | 18 months after shipments and 12 months after installed |

| Valve Structure | Flange Forged Swing Check Valve |

| Valve Delivery | 15 - 30 days |

| Valve Sample | Sample Available by Didtek Valve |

| Valve Color | Customer request |

| Valve Packing | Plywood Case for Check Valve |

| MOQ | 1 Set |

| Valve Certificate | API6D/CE/ISO9001/ISO14001 |

| Place of Origin | Zhejiang, China (Mainland) |

| Delivery Detail: | Shipped in 15-30 days after payment |

| Port | Shanghai Or Ningbo |

| Payment Terms | L/C,D/A,D/P,T/T, Western Union |

Standard Material Specifications

| NO. | Part Name | CS to ASTM | AS to ASTM | SS to ASTM | |

|---|---|---|---|---|---|

| Type A105 | Type F22 | Type F304(L) | Type F316(L) | ||

| 1 | Body | A105 | A182 F22 | A182 F304(L) | A182 F316(L) |

| 2 | Piston Disc | A276 410 | A276 304 | A276 304(L) | A276 316(L) |

| 3 | Gasket | Corrugated SS + graphite | SS + PTFE | ||

| 4 | Bonnet | A105 | A182 F22 | A182 F304 L | A182 F316(L) |

| 5 | Nameplate | SS | |||

| 6 | Bolt | A193 B7 | A193 B16 | A193 B8M | A193 B8M |

| 7 | Ball | A182 F304 | A182 F304 | A182 F304 | A182 F304 |

| Suitable Medium | W.O.G.etc | W.O.G.etc | HNO3CH3OOH etc | ||

| Suitable Temperature | -29 425 | -29 550 | -29 180 | ||

Note: Other materials are available upon request.

Dimensions (mm) and Weights (Kg)

| NPS | Conv. | 3/8 | 1/2 | 3/4 | 1 | 1-1/4 | 1-1/2 | 2 | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Full | 3/4 | 1/2 | 3/4 | 1 | 1/4 | 1-1/2 | 2 | |||

| L | 79 | 79 | 92 | 111 | 120 | 152 | 172 | 200 | ||

| H | 61 | 61 | 65 | 79 | 95 | 103 | 118 | 132 | ||

| Weights | Bolted | 1.4 | 1.2 | 1.5 | 3.1 | 3.9 | 5.6 | 8.9 | 12.5 | |

| Welded | 1.1 | 1.0 | 1.2 | 2.9 | 3.3 | 4.9 | 8.1 | 10.9 | ||